Sheep Cheese Making: From Milk to Deliciousness

At Quesería La Antigua de Fuentesaúco, the production of sheep’s cheese is an art that has been perfected over the years. It is not only a meticulous process, but also a history of tradition and dedication that transforms milk into an exquisite delicacy. In this article, we will explore the sheep cheese making process in detail, with a special focus on the amount of milk needed and the shrinkage that occurs during curing.

The Raw Material: Sheep’s Milk

To make a good sheep’s cheese, the quality of the milk is fundamental. Sheep’s milk is rich in nutrients, including proteins, fats and minerals, making it ideal for the production of high quality cheeses. On average, a sheep can produce between 1 and 2 liters of milk per day, depending on the breed and management conditions.

Amount of Milk Needed

To produce one kilogram of sheep’s cheese, approximately 5 liters of milk are needed. This number can vary according to the type of cheese and the processing method, but in general, the ratio of milk to cheese remains fairly constant. The amount of milk used is crucial in determining not only the amount of cheese produced, but also its texture and flavor.

The Elaboration Process

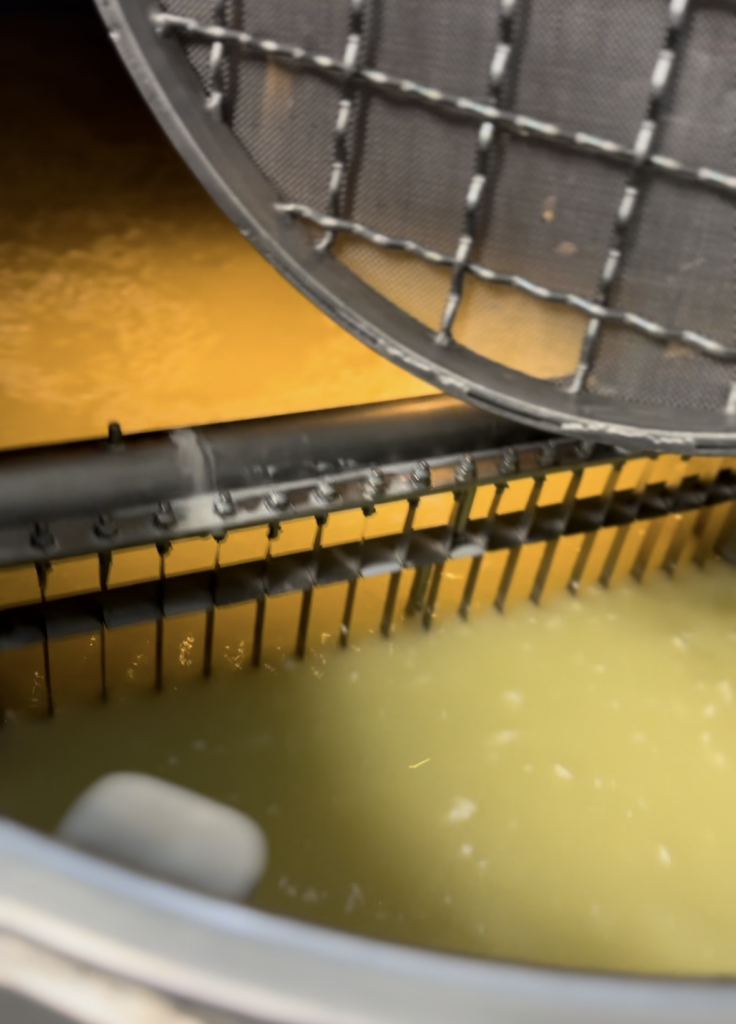

The process of making sheep’s cheese begins with the coagulation of the milk, a critical step that involves the addition of rennet. Once the milk has coagulated, the curd is cut into small pieces to facilitate the release of the whey. This whey is separated from the curd, which is then molded and pressed to remove more whey and shape the cheese.

The Decline During Healing

Once the cheese has been molded and pressed, the curing stage begins. During this process, the cheese loses a significant amount of weight due to the evaporation of water and the continuous elimination of whey. This loss, known as shrinkage, can be considerable. In general, a cheese can lose between 10% and 30% of its initial weight during curing. For example, if we start with a cheese weighing 2 kilograms, it may end up weighing around 1.5 to 1.8 kilograms after several months of curing.

Factors Affecting Shrinkage

The amount of shrinkage depends on several factors, including the humidity of the environment, the curing temperature, and the duration of the process. At Quesería La Antigua de Fuentesaúco, we carefully control these variables to ensure that each cheese reaches its maximum quality. Slow, controlled curing allows the flavors to fully develop, resulting in a final product that is truly exceptional.

The End Result: An Exquisite Sheep Cheese

After curing, the sheep cheese is ready to be enjoyed. At Quesería La Antigua de Fuentesaúco, we pride ourselves on producing cheeses that reflect the rich tradition and know-how of our region. Each piece of cheese is the result of a long and careful process that begins with the milk of our sheep and ends with a product that delights the senses.

Conclusion

Sheep cheese making is a fascinating and complex process that goes beyond the simple transformation of milk into cheese. From the amount of milk needed to the shrinkage during curing, each stage of the process is crucial to produce a high quality cheese. At Quesería La Antigua de Fuentesaúco, we are dedicated to perfecting this art in order to offer our customers the best sheep cheeses.

If you have ever wondered what it takes to make a delicious sheep cheese, now you know that behind every bite there is a lot of work, patience and love for tradition. Come visit us and discover for yourself the incomparable flavor of our sheep cheeses.

By the way, do you know the best way to preserve cheese at home? We show you how to do it! You can still see it here.

See you in the next blog friends! By the way, have you seen our last entry about olive trees in our gardens?

See you soon and long live cheese!